Call

"From hours to minutes, our innovation transforms the way you work, ensuring seamless transitions & unmatched efficiency."

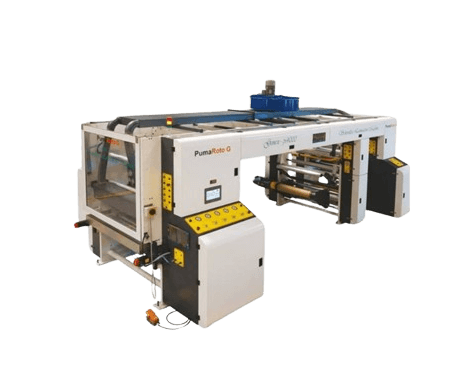

The Solvent less Lamination Machine introduces an innovative automated roller fitting system, obviating the need for manual intervention and significantly mitigating the risk of human error. By harnessing the power of automation, PumaRotoG ensures unparalleled precision and consistency in the lamination process, setting a new benchmark for quality and reliability. The genesis of this remarkable invention stemmed from a common dilemma faced by many MSMES: the need to enhance productivity while reducing operational complexities and costs. One such MSME approached us with a specific set of challenges: they struggled with small job quantities for lamination, compounded by the necessity to process multiple jobs within a single day. The frequent job changes not only hampered productivity but also incurred substantial downtime, averaging around 1 to 1.5 hours per changeover. PumaRotoG, led by CEO Mr. Prasad Annayyappa, and marketing leader Star Flexi Films, directed by Mr. Ashish Savia , have introduced revolutionary technology, reshaping industry standards.

A standout feature is its remarkable reduction in job changeover time, slashing what was once a 60-minute task to a mere 10 minutes. With PumaRotoG's Solventless Lamination Machine, that dream is now a reality by transitioning between diverse jobs with minimal disruption, maximizing work time, and eliminating costly downtime. Our machine boasts an impressive 80-micron gap setting time, reducing it from a laborious 30 minutes to a lightning-fast 10 seconds. Such unprecedented speed and precision are unmatched in the industry, making our solution a game-changer for MSMEs worldwide.

PumaRoto G has features like motorized auto-indexing for fixed rollers, eliminating manual hassles. The machine's Secondary Split Roller ensures optimal performance, while its shaft less unwind and rewind system minimize downtime. Plus, precision machined hollow idler rollers guarantee impeccable results every time.

In an exclusive interview with Packaging Today Magazine, we explored the remarkable journey of Star Flexi Films with its visionary directors, Kevin Mehta and Ashish Savia. Their story exemplifies how A Decade of Impressive Growth strategic vision, technological innovation, and sustainability can drive industry leadership.

Reflecting on the company's evolution since its founding in 2009. shared their exceptional growth. "We started with a modest turnover of 15 lakhs," he said. "Within two years, we reached *1 crore, and by the end of our fifth year, our turnover soared to 10 crores. By our tenth year, we proudly achieved e50 crores. This remarkable ascent from trading and importing to becoming a leading dealer and marketing agency for www.packagingtoday.com brands like PumaRoto G and Jiang Chovyting underscores our strategic vision and adaptability."

This impressive growth highlights Star Flexi Films' ability to evolve and thrive amidst industry challenges. Their success underscores a robust business model and strategic foresight, setting a benchmark for transformative success in the packaging industry. Turning to technological advancements, Ashish Savia introduced their groundbreaking Turning to "Rotogravure Machine without Cylinder Technology." "Developed in collaboration with PumaRoto G, this technology allows high-speed printing with water-based inks at speeds exceeding 300 meters per minute, eliminating traditional cylinders.

This innovation boosts production efficiency and reduces printing costs by 50- 60%, setting a new eco-friendly benchmark," he explained.This advancement marks a significant shift, showcasing Star Flexi Films' role as a leader in the industry. Their commitment to efficiency and sustainability is paving the way for a greener future in packaging.

Ashish Savla emphasized the company's dedication to sustainability. "Our approach is integral to our operations," he said. "Our technology reduces material waste and energy consumption. Water-based inks minimize harmful emissions, and Our technology promotes a circular economy by enhancing operational efficiency and reducing our carbon footprint. The 50% reduction in printing costs demonstrates our ability to innovate while maintaining cost efficiency."

Star Flexi Films' proactive approach to sustainability is commendable and necessary.

Their efforts to minimize environmental impact and promote circular economy principles set a high industry standard, inspiring responsible business practices.

Looking ahead, shared their ambitious vision: "We aim to become a global leader in manufacturing and trading, recognized for innovative solutions and dedication to sustainability. Our mission is to deliver superior products, build long-term relationships, and contribute to community development."

Their forward-looking vision is both inspiring and strategic. Focusing on global leadership and ethical practices, they demonstrate dedication to long- term success and positive impact.

When asked why Star Flexi Films deserves recognition, Ashish Savia highlighted several key factors. "Our innovation is evident with India's first hybrid machine. We challenge traditional norms with significant R&D investments. Our patent- pending technology underscores our commitment toinnovation and quality, positioning us as industry frontrunners."

Looking to the future, shared an ambitious vision. "We aim to become a global leader in manufacturing and trading. recognized for our innovative solutions and dedication 10 sustainability.

Ashish Savia's insights reflect a decade of extraordinary growth and visionary leadership. Their achievements and future goals showcase a company that leads and inspires, setting a new benchmark for the packaging industry.

In the fast-paced world of printing, customer demands are becoming increasingly specific, and jobs are getting smaller. Innovation is key. and Puma Roto G has risen to the occasion with a Shaftless Rotogravure Printing Machine that can handle small-dimension jobs down to an incredible 400mm width. Yes, 400mm-and this is not just another feature. It's precisely what the market has been asking for.

The printing industry is evolving quickly, with a surge in demand for small-size print jobs-narrower widths, shorter runs, and faster turnarounds. However, most existing shaftless rotogravure machines handle widths around. 1000mm, which isn't ideal for smaller jobs. That's where Puma Roto G, under the leadership of CEO A. Prashant, Machine is designed to meet the demand for smaller jobs. comes in. Their new Shaftless Rotogravure Printing with an unmatched capability of handling jobs as small as 400mm wide.

So why focus on 400mm? Today's customers want shorter print runs, greater customization, and quicker turnarounds. Printers need machines that switch jobs quickly and efficiently, but most existing machines are built for large-scale jobs, not the flexibility required for smaller ones.

Puma Roto G's solution isn't just a response to this market need-it's a game- changer. Their machine provides the versatility to handle both small and large jobs, bridging a gap in the industry and setting new standard for a innovation.

This innovation wouldn't be possible without the partnership between Puma Roto G and Star Flexi Films, their exclusive global marketing partner. Led by directors Ashish Savia , Star Flexi Films brings deep industry expertise and market insight, ensuring that this breakthrough reaches printers worldwide. Together, they're redefining the future of printing, making it faster, smarter, and more responsive to market needs.

Traditional shafted machines can handle small jobs but require lengthy changeovers. Shaftless machines are quicker but limited to larger jobs-until now. Puma Roto G's new machine offers job changeovers in just 10 minutes, allowing printers to switch between jobs rapidly, without compromising on quality. With no bending shafts or alignment problems, it's high-quality printing, every time, and maintenance-free.